You get the widest range of adhesives at CTA. Choose from our Two Part Structural Acrylic, Two Part Polyurethane, Toughened Epoxy Resins, High Temperature, Polyolefin Bonders. Cyanoacrylate, Contact adhesives, Anaerobic, Single Component Polyurethane, UV Curing or Hot Melt.

If you are unable to find what you are looking for or are not sure if an adhesive is right for your application, contact us. Talk to us about your application we have the technical knowledge and expertise to assist you in deciding which adhesive is most suited to your application. Contact Page

The majority of all our adhesives and tapes are manufactured right here in the UK.

2000 Series Two part structural acrylic adhesive

Our 2000 series of adhesives are all two part adhesives with 1:1 and 10:1 ratios, meaning the adhesive and the activator are equal size. Our 2000 series range from Structural Acrylic (Methyl Methacrylate), Reinforced Polyurethane or Epoxy resins. The strongest of these adhesives would be the Methacrylate adhesive, high temp resistance, tensile and shear performance. Capable of filling gaps up to 10mm whilst maintaining it’s structural strength and characteristics and capable of going through a powder coat oven short term at 220°C. Open times vary from 1 – 40 minutes. Our strongest two part adhesive is our 2105 and also our biggest selling item. Polyurethane adhesives have low or no odour or shrinkage and are more environmentally friendly. Epoxy resins are traditional yet still have have a unique quality as they are available clear and can be better at bonding some metals such as copper and brass with open times varying from 3 – 35 minutes.

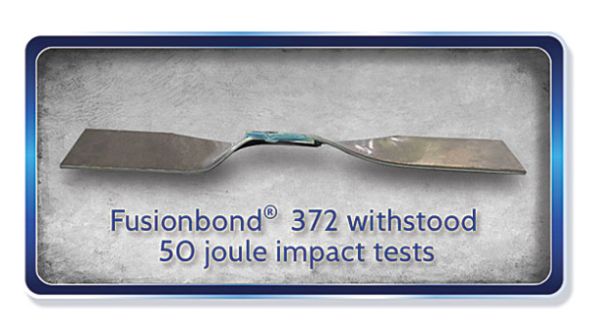

Methacrylate adhesives are supplied in a two part system that when mixed offer a controlled cure speed suited to the application. The cured adhesive can offer incredibly high tensile, shear and peel strength, whilst also resisting impact loads at both elevated and sub zero temperatures.

- Trial Kits Two Part Adhesives

- Two Part Structural Adhesive 2104 Pink & Green

- Two Part Structural Adhesive 2105

- Two Part Structural Adhesives 2115

- Two Part Structural Adhesive 2120

- Two Part Structural Adhesive 2150

- Two Part Crystal Clear Adhesive 2155

- Two Part Structural Adhesive 2102 Polyolefin Bonder

- Two Part Structural Adhesive 2206

CTA 2105 400ml

Reinforced Polyurethane and Epoxy resins are particularly good for composite bonding along with many different types of plastics. Our epoxy range is also sold in cartridge format and are 1:1 ratio. Our range of polyurethane products can be purchased on cartridges or bulk kits. If you have a specific requirement please do not hesitate to contact us to see if we have a formulation that suits your application.

Anchor fixing chemical adhesive is a rapid curing “one shot” two part anchoring cartridge system based on an epoxy acrylate resin. Combining the benefits of epoxy resin (toughness, heat and chemical resistance) with the handling and rapid curing of polyester resins.

- Trial Kits Two Part Adhesives

- Toughened Epoxy Resin 2605

- Toughened Epoxy Resin 2620

- Toughened Epoxy Resin 2650

- Reinforced GRP Polyurethane adhesive

- Crusher Backing

- Anchor Fixing chemical adhesive

- Grass glue 22732

CTA 2605 400ml

1000 Series Single part adhesives

The 1000 series of adhesives are all one component adhesives they can cure atmospherically (moisture curing), Ultraviolet Light activated (UV) or anaerobicly (in the absence of air) such as thread lockers and retaining compounds i.e. applying a sealant to the thread of a bolt. Once applied into the screw hole where there is no oxygen the sealant will then cure in the absence of air.

Hybrid adhesive – This range of single part adhesives have been specifically designed from a blend of raw materials to be cured within an oven and continue to cope with high temperatures. Making it ideal when needing to form a seal prior to a powder coating process. Our newly improved 16002 Pre Powder coat seam sealer is quickly adapting itself in many industries replacing the need to spot weld saving time in manufacturing processes.

- Cyanoacylate (Super Glue) 1105 LV

- Cyanoacylate (Super Glue) 1106 PR

- Cyanoacylate (Super Glue) 1110 MV

- Cyanoacylate (Super Glue) 1115 HV

- Clear Rubber Toughened 12435

- Black Rubber Toughened 1135

- Cyanoacylate Gel 1154

- Bonding Kits (Mitre Mate) 1160

- Activator Spray 1191

- Activator Spray 75 NF – (None Flammable)

Cyanoacrylate Adhesive – Cyanoacrylates are a family of strong fast-acting adhesives. When used in conjunction to an activator a set time as quick as 30 seconds can be achieved. This type of adhesive is sometimes known generically as instant glues or superglues. Our strongest Cyanoacrylate and best selling is our 1115 HV.

Contact Adhesives – are products that will cure off once the solvent/aqueous (water based) has evaporated so can be a blend of rubber/polyurethane adhesives suspended in either a solvent or water based. Our 1210 (solvent based) contact adhesive is our most popular and comes in a handy 1 litre can that can be brushed onto the substrate which requires bonding.

- Low Strength Thread Locker 1225 purple

- Medium Strength Thread locker 1226 Blue

- High Strength Thread Locker 1227 green

- High Strength Bolt Lock 1228 red

- Thread Locker 1243 blue

- Bearing Lock 1231

- Bearing Lock 1238 HT

Thread & Bearing Lock – We offer a great high quality range of thread and bearing/bolt lockers at fantastic prices, our customer are blown away by our range.

- Synthetic Grass Glue

- Instant Grab Adhesive 17310

- Polyurethane Green 12854

- Polyurethane Sealer 15125

- Polyurethane Adhesive Sealant 12126

- Polyurethane High Grab 15330

- MS Polymer High Grab 15500

- Mirror Adhesive

- Silicone General Purpose

- Silicone High Temperature

Polyurethane & Hybrid adhesives – This range of adhesives are single part cartridge adhesives, our biggest selling single part PU is 12126 available in black, white or grey. Ideal for bonding a wide range of building materials, without the need for nails or screws. Initial grab sets to form an extremely high strength bond a multi purpose and gap filling adhesive which can be sanded and over painted. Also view our 15500 Clear an MS (Modified Silane) Polymer High Grab Adhesive and an all-round durable, flexible adhesive and sealant based on MS Polymer technology providing excellent adhesion to non-porous surfaces and is paintable with most paints. Can be applied on damp surfaces. Both products keenly priced within the market place.

Polyurethane & Hybrid adhesives – This range of adhesives are single part cartridge adhesives, our biggest selling single part PU is 12126 available in black, white or grey. Ideal for bonding a wide range of building materials, without the need for nails or screws. Initial grab sets to form an extremely high strength bond a multi purpose and gap filling adhesive which can be sanded and over painted. Also view our 15500 Clear an MS (Modified Silane) Polymer High Grab Adhesive and an all-round durable, flexible adhesive and sealant based on MS Polymer technology providing excellent adhesion to non-porous surfaces and is paintable with most paints. Can be applied on damp surfaces. Both products keenly priced within the market place.

UV Curing Adhesives – are activated by an ultraviolet or UV ray of light.

- 130012

- 130015

Hot melt adhesives – Our hot melt adhesives are sticks of adhesive that when heated will melt to form a thixotropic fluid adhesive that, once cured, will re-solidify to bond desired materials.

Accessories

• Primers and UV Identifiable Primer

• Release Agents

CTA IPA Cleaner / Degreaser Kit

At Central Tapes & Adhesives we pride ourselves on sharing our technical knowledge and expertise with our customers to ensure they have the correct adhesive for the application. Please talk to us about your application. Contact us today

Our comprehensive range of adhesives are supplied into the majority of industries such as Signage, Point Of Sale, Plastic Moulding, Metal Fabrication, Construction, Automotive, Furniture, Recycling and many more.