Toughened epoxy resin 2650 is an epoxy adhesive and part of our structural bonding range. This product is often specified when bonding a variety of surfaces, such as worktop joints, glass and plastic components.

This product is available in 50ml, 400ml and bulk upon a made to order request.

For stock items please see:

Two part toughened epoxy resin 2605 (3-4 minute working life and a 5-7 minute fixture time)

Two part toughened epoxy resin 2620 (25-35 minute working life and a 40-45 minute fixture time)

Benefits of toughened epoxy resin 2650

- This adhesive is capable of bonding aluminium, steel, engineered plastics and composites together.

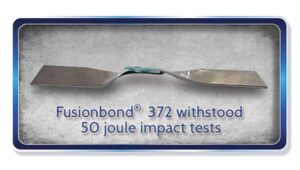

- Toughened epoxy resin 2650 has high temperature resistance, tensile and shear performance.

- This type of toughened epoxy is a great alternative to the well known epoxy resins, adhesives or glues such as Araldite etc.

- Working time: 25 – 35 minutes

- Fixture time: 40 – 45 minutes

- Temperature range: -50°C to +60°C

- Capable for filling gaps up to 3mm

Epoxy product information

Toughened epoxy resin 2650 is a typical two part system (a hardener and a resin) that, when mixed, will solidify due to polymerisation. This chemistry is very stable and can be modified and filled with ease, allowing us to attain a wide variety of cured attributes from a single base product. For example, silver can be added to attain conductivity, quartz fillers can be added to improve impact resistance.

This versatile chemistry produces typically long open times and rigid bonds, and is available in a range of viscosities; from flowable liquids to thixotropic pastes.

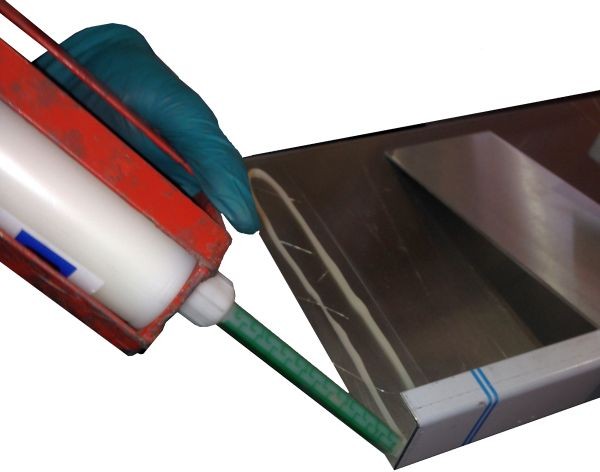

How to apply toughened epoxy resin 2650

Our toughened epoxy resin 2650 has a 25 – 35 minutes working life with a 40 – 45 minutes fixture time. Before dispensing, ensure that surfaces are clean, dry and free of any dirt, dust and grease. For the best results, we recommend using CTA IPA Cleaner Degreaser.

- Use sufficient pressure over the whole surface at room temperature to ensure maximum adhesion to substrates.

- The ideal application temperature is between 15 – 25°C.

- Primers can increase the bond durability and surface tension for difficult to bond materials. We recommend CTA Primer or CTA UV Identifiable Primer to achieve the best results.

- Ensure uniform stress distribution.

For more information, read our two part adhesives FAQs and guide to surface preparation for adhesives and best working practice.

Purchasing information

We have a comprehensive range of epoxy glues, epoxy resins and alternatives to other manufacturers’ epoxies, for bonding metals or plastics together.

Our toughened epoxy resin 2650 is available in clear and black, in 50ml and 400ml, for use with manual or pneumatic applicator guns and nozzles. If a larger volume is required, we are able to supply 20 litre pails and 200 litre drums, which also require bulk dispensing units. Trial kits are also available for this product. For more information, please contact us. All prices are inclusive of VAT.

View our full range of two part structural adhesives below:

| Product | Working time | Fixture time | Type | Colour | Cartridge size | Key Features |

|---|---|---|---|---|---|---|

| 2102 | 4-7 mins | 220 mins | Hybrid / Methacrylate | Neutral | 50 / 400ml | LSE Plastics Low energy plastic bonder |

| 2104 | 2-4 mins | 4-7 mins | Acrylic | Pink & green | 25 / 50 / 400ml | Metals, plastics and composites |

| 2105 | 5-7 mins | 7-10 mins | Methacrylate | Neutral / Black | 25 / 50 / 400ml | Metals, plastics and composites |

| 2120 | 12-15 mins | 20-25 mins | Methacrylate | Neutral / Black | 50 / 400ml | Metals, plastics and composites |

| 2140 | 35-40 mins | 70-80 mins | Methacrylate | Neutral | 50 / 400ml | Metals, plastics and composites |

| 2155 | 1-2 mins | 4-5 mins | Methacrylate | Clear | 50 / 400ml | Sign making |

| 2206 | 2-4 mins | 4-6 mins | Methacrylate | Black | 50 / 490ml | Metals, plastics and composites |

| 2605 | 3-4 mins | 5-7 mins | Epoxy | Clear | 25 / 50 / 400ml | Composites, Plastics and Malleable metals |

| 2620 | 25-35 mins | 40-45 mins | Epoxy | Clear | 50 / 400ml | Composites, Plastics and Malleable metals |

| 25-5 | 210 seconds | 15 mins | Polyurethane | Black | 50ml | Composites and plastics |

If you have any questions, don’t hesitate to contact us via the yellow chatbox, fill out our online contact form, email us at [email protected] or call us directly on +44 (0) 121 378 2909.