It’s great when one of our loyal and longstanding customers is more than happy to write about the appreciation they have for one of our products. Talking to us about how and why a particular product has been successful for them, and that they trust our product… it really does make being in this sticky business of adhesives and tapes all worthwhile!

Below we have an account from Luke Kelso, Operations Manager at Rubber Box Co Limited.

Why we trust CTA Adhesives

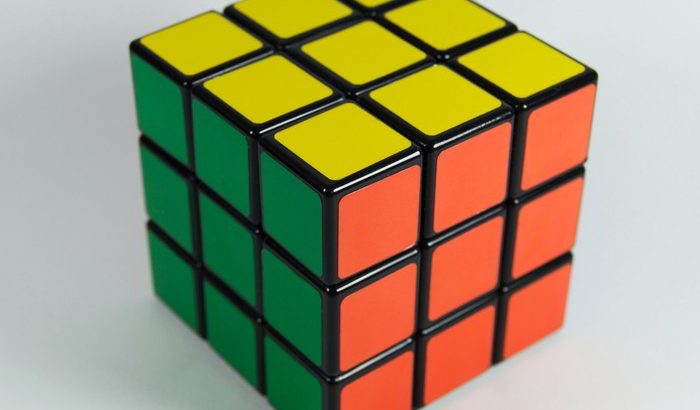

As the UK’s leading manufacturer of power distribution boxes, we supply the likes of F1, MotoGP, International Football, Rugby, the Commonwealth Games… our boxes were also part of the Olympic opening and closing ceremonies. There is no question about it, we need products we can trust so we can confidently supply our power units effectively.

One product in particular that has stood the test of time for us is CTA 1135 Black Rubber Toughened Cyanoacrylate Adhesive. When it comes to critical components for our products, we don’t take chances. For over sixteen years, we’ve trusted CTA’s adhesives exclusively, their performance has never let us down.

Our rubber boxes travel around the globe, in fact they are deployed to some very extreme environments, including harsh deserts in America. We have used hundreds of units of adhesive from CTA and not a single bonded power box has ever failed. In reliability engineering terms that is a zero-failure life test over sixteen years for us, that’s just how good it is.

How this high strength rubber adhesive works for us

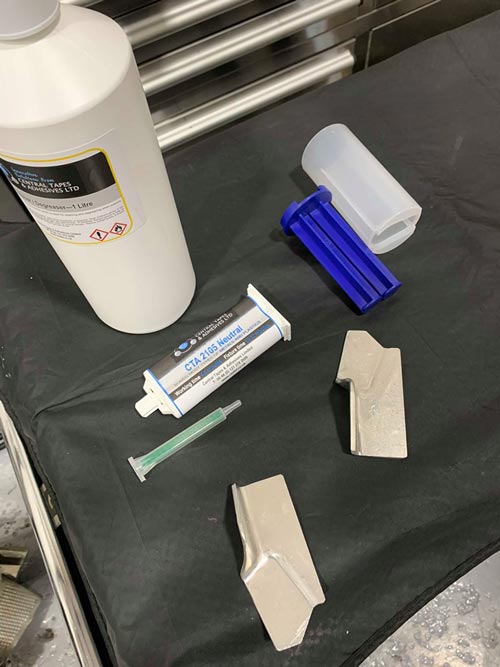

We use CTA 1135 high strength rubber adhesive to bond two sections of our rugged boxes together as pictured here. We also use the adhesive to attach the box handles also pictured below, some of the loads we deal with exceed 75kg and, as mentioned previously, not a single failure. CTA 1135 is a high viscosity, fast curing, black, rubber toughened super adhesive, “super” being the standout word here.

Our rubber boxes are not just storage containers, they’re high performance, high-load, power distribution units and dependability is non-negotiable. With CTA adhesives, we have found a product we can truly count on – strong, tough and proven to be effective across thousands of challenging uses.

Final words

“If you’re looking for industrial-grade performance you can trust year after year, CTA delivers.”

Luke Kelso, Operations Manager

And our reply…

“Thanks Luke, it’s always good to hear that our commitment to providing the right solution to a challenging bonding issue, is rewarded with your continued faith and custom.”

Mark Plimmer, Managing Director – CTA Industrial

James goes on to say “The tape is absolutely perfect! It is much stronger than I had expected and is exactly the right thickness and width, and very easy to trim with a blade afterwards. It worked like a dream! This method of combining the use of modern primers and paints with CTA’s tape should prevent the dreaded electrolysis of aluminium touching steel. It should now last another 64 years!”

James goes on to say “The tape is absolutely perfect! It is much stronger than I had expected and is exactly the right thickness and width, and very easy to trim with a blade afterwards. It worked like a dream! This method of combining the use of modern primers and paints with CTA’s tape should prevent the dreaded electrolysis of aluminium touching steel. It should now last another 64 years!”