CTA were asked to help a client who had a special automotive bonding request on this stunning supercar.

What was your brief from the client?

They wanted to strengthen the framework and bulkhead of this impressive Audi R8. The R8 is the German car maker’s only mid-engine machine which has gained a reputation in recent years for being “The everyday supercar”. It’s a high quality performance car that demands extreme structural integrity.

Our ‘mission’ was to reinforce the bulkhead near to the suspension components. The brackets themselves were supplied by Audi, so our task was to ensure that we could perfectly bond the two parts and create a high quality, effective reinforcement commensurate with such a prestige automotive product.

What product did you recommend and why?

CTA have a superb range of automotive adhesive and tapes suitable for many applications from panel and trim bonding to specific die cut tapes. Because of this, we had to make certain that we identified the best one for the Audi application. The adhesive would need to prove itself in a demanding metal to metal bonding application to reinforce the bulkhead near the suspension components. We immediately thought of our two-part structural adhesive 2105, as this is suitable for composites or metal brackets (such as cladding), and for GRP / FRP composite structures. For bonding metal to composites, 2105 obtains a higher shear strength than the composite layers, therefore achieving a structural bond between the metal and the composite panel. It is an excellent engineering and manufacturing adhesive. It also has a five-minute working life, a 12 minute fixing time, is capable of filling gaps up to 10mm whilst maintaining it’s structural strength and characteristics – and comes in a choice of a neutral or black finish!

The technical stuff that we love!

A methyl methacrylate is the methyl ester of methacrylate acid. Its primary use is to manufacture a number of different plastics, but it is also the main ingredient in our range of metal adhesive products.

Methacrylate adhesives are supplied in a two-part system that, when mixed, offer a controlled cure speed suited to the application. The cured adhesive can offer incredibly high tensile, shear and peel strength, whilst also resisting impact loads at both elevated and sub-zero temperatures.

The unique chemistry of our two-part structural adhesive 2105 is unrivalled in terms of convenience, ease of use and superior mechanical strength. Use for bonding engineered plastics, composites, steel, aluminium and other alloys. This is metal bonding glue at it’s best.

Client feedback

The feedback we received from the client was excellent and he told us that it was easy to apply following on from the preparation process. He told us:

“I just wanted to send you a couple of photos of the small project that I have had recently done using one of your products. The images are of frame reinforcing plates in aluminium attached to the front bulkhead of an Audi R8. The job went without a hitch and I am very pleased with the outcome. Thank you for all your guidance.”

Trevor Hartland

Lessons learned?

Although this was only a ‘small’ job, it still required our technical expertise and knowledge. As more and more clients challenge us with bonding application dilemmas, it cements our belief that our comprehensive range of products ideally support diverse challenges, regardless of whether the jobs are large or small. We pride ourselves on being ‘technical experts’, and welcome challenges such as this.

A powerful structural adhesive for the modern age

We knew that our CTA 2105 Structural Adhesive product would be perfect for this task. It’s a versatile product used in many industries and it lends itself well to automotive bonding requirements. To create a strong and reliable bond relies upon pristine preparation, so we talked our client through the cleaning and preparation process. We have a short instructional video here:

A walkthrough of the bonding process

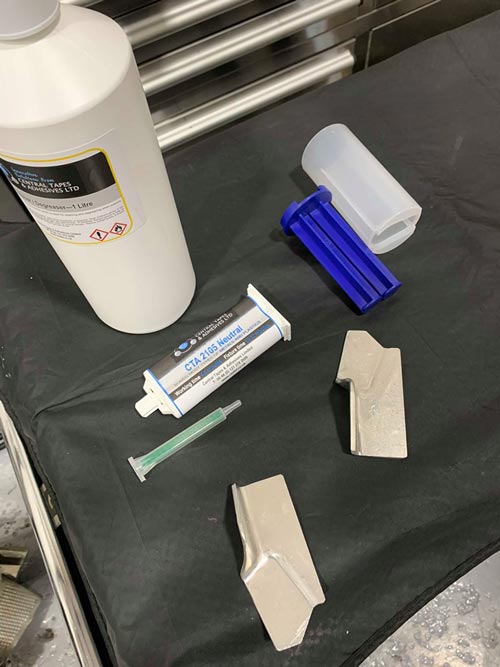

We always recommend the use of our specially formulated CTA IPA Cleaner Degreaser to ensure that surfaces are clean, dry and free of any dirt, dust and grease. We also talked our client through the best working practice and how to maximise the potential of the adhesive. Here are the parts prepped ready for bonding:

The outline of the new part (provided by Audi) was marked to provide a guide for final location:

The end result was a professional reinforcement that is designed to last:

In summary…

Contact us with ALL your bonding application challenges – we are waiting to fix them for you! If you would benefit by switching to our more advanced structural adhesives and wish to discuss a product or application, please get in touch with us today.