Construction Adhesives sealants and membrane tapes offer several advantages in the construction sector. These range from water tight sealing joints, glazing windows and doors, Fire retardant breathable membranes and colour matching silicone.

Adhesives, Sealants and tapes used in the Construction Industry

Structural Glazing Tape, Expanding Foam Tape, Premium Glazing Silicone, Fire Retardant Membrane Tape

External Membrane Tape, 12126 Adhesive Sealant, Colour Match Silicone, 2105 Structural Adhesive.

Products used within the Construction Industry

Structural Glazing Tape

Structural Glazing Tape (SGT), is a specialised adhesive system used in the assembly of windows, doors, and skylights, collectively referred to as fenestration units.

Our SGT acts as a high-performance bonding interface system, positioned between the integrated glass unit (IGU) and frame. Particularly within commercial glazing applications such as curtain walls, skylights, and storefronts. It has fast recovery from compression and has been tested to ASTM E96-2005 water vapour transmission to determine open cell airflow structure.

Expanding Foam Tape

Expanding foam tape is used specifically for the glazing industry. It is an open cell polyurethane foam impregnated with flame retardant acrylic resin backed with an acrylic adhesive on one side. Expanding foam tape is a type of sealing material made from pre-compressed foam that gradually expands once opened and exposed to air after application. It’s commonly used in construction and home improvement projects to seal joints, gaps or seams against air, water, dust and noise. Heavily impregnated with chemically stabilised acrylics creating flame retardant properties, Expanding foam tape remains permanently elastic and will continually self adjust after installation to keep gaps closed.

Premium Glazing Silicone

Premium Glazing Silicone Sealant is a clear high quality, low modulus, neutral curing (Oxime) silicone, specifically formulated for use in glazing systems. Glazing silicone is used in the installation of glass in windows, doors, curtain walls, skylights, and other architectural glazing applications. It is a flexible, durable, weather-resistant silicone-based compound, that creates a clear waterproof, airtight seal between glass and frame or other building materials. Glazing silicone contains fungicides making it suitable for many applications. It provides a long lasting watertight seal for interior and exterior applications. Packaged in a 310ml cartridge. Clear in colour.

Fire Retardant Membrane Tape

Fire retardant breathable membrane tape is a black foil high tack tape. This FR (B-s1, d0) membrane tape is used to seal Windows, Doors, Curtain Walls, Façade cladding and many more construction watertight applications. It provides a range of significant benefits to the construction industry, especially in modern building envelopes where fire safety, durability, and performance are paramount.

External Waterproof Membrane Tape

Our range of external waterproof membrane tapes are very high tack and suitable for sealing Windows, Doors, Curtain Walls, Façade cladding and many more construction watertight applications. With this high performance adhesive tape it sticks immediately upon application which is critical in high-wind or vertical surface installations. It has weather proofing and moisture control properties which act as a barrier against water, air and vapour. Bonding well to concrete, wood, metal and insulation boards making it versatile across different parts of a building envelope.

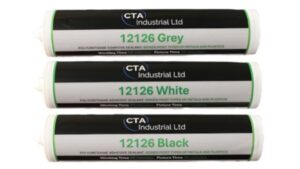

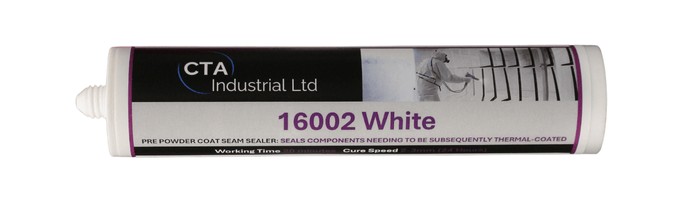

12126 Adhesive Sealant

Polyurethane adhesive sealant 12126 is a one component, fast curing, high modulus polyurethane sealant ideal for a wide variety of sealing and bonding applications. CTA 12126 has an advanced rheology making it easy to gun, but with an excellent slump resistance. The modified curing system means this product has exceptionally low isocyanate content. Non hazardous for all means of transport.

This high quality product cures on exposure to atmospheric moisture to form a tough, resilient, elastic rubber compound which ensures a flexible joint (shore A 40). Good resistance to many chemicals.

Due to its elastic properties CTA 12126 has found applications in the construction, flooring and roofing.

Use our polyurethane adhesive to bond stainless steel, metals, wood, glass, plastics, stone, masonry, ceramic tiles and other materials. This product is also known as grab adhesive.

Colour Match Silicone

CTA Colour Match Silicone Sealant can be matched by RAL numbers. It is a premium quality, low modulus, neutral curing (Oxime) silicone sealant which contains fungicides making it suitable for use as a sanitary sealant, as well as many other sealant applications. It provides a long lasting watertight seal for interior and exterior applications. We can colour match our silicone in as little as 12 tubes (MOQ 12 tubes per box).

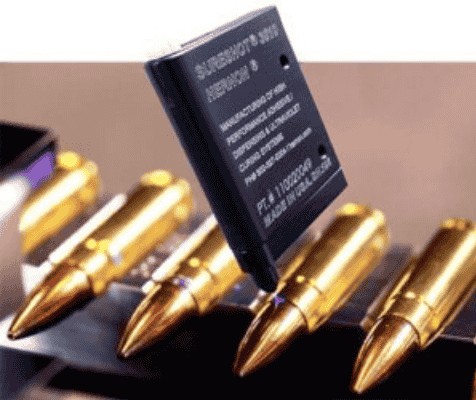

2105 Structural Adhesive

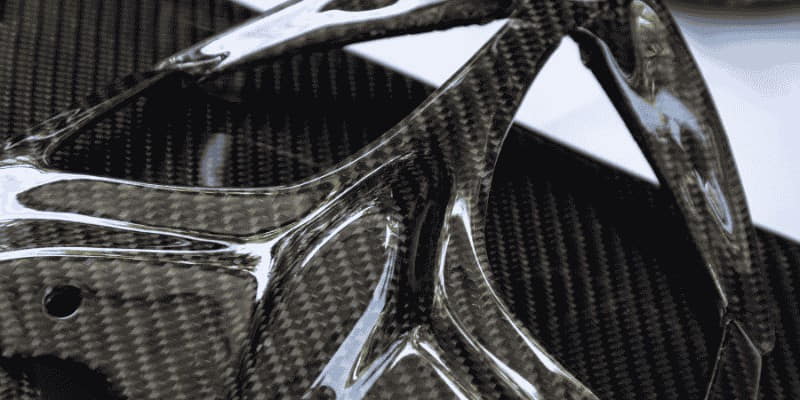

Our two part structural adhesive is much more than just a metal glue, it’s a very versatile, Methacrylate acrylic adhesive and part of our structural bonding range. This product can be used to bond or glue various metal joints together in architectural cladding applications. It is used extensively as a metal-to-metal glue, steel-to-steel, or aluminium-to-aluminium adhesive. It has a high temperature resistance, tensile and shear performance.

Our two part structural adhesive 2105 is also suitable for composites or metal brackets to GRP / FRP composite structures / Carbon fibre. For bonding metal to composites, 2105 obtains a higher shear strength than the composite layers, therefore achieving a structural bond between the metal and the composite panel. It is an excellent engineering and manufacturing adhesive.

Structural acrylic tapes

Structural acrylic tapes have typical mixtures of acrylic polymers, which are inherently pressure sensitive adhesives. This range of structural foamed acrylic tapes completes our high strength bonding range. There are many advantages of using foamed acrylic tapes as apposed to traditional mechanical fixings, our high bond tapes have excellent wet out properties and are unaffected by ageing and UV (no discolouration). In addition they allow for even stress distribution over the full bond area and also when bonding dissimilar materials these products allow for thermal expansion.

Our 6000 series is predominantly suitable for internal as well as external applications due to its thickness and excellent elongation. It is capable of absorbing shock and vibrations, the firm acrylic mass has a extreme internal strength. Available in various colours and thicknesses with a unique ability to bond various substrates such as metals, plastics, glass and more challenging applications.

Here are some typical applications for adhesives, sealants and tapes in the construction sector:

- Curtain wall and façade systems

- Cladding and panel bonding

- Flooring and subfloor systems

- Fire resistant assemblies

- Window and Door installation

- Modular construction

We believe that adhesives and tapes are valued in the construction sector due to their versatility, strength and aesthetic properties along with their ability to provide bonding solutions for modern, energy efficient and sustainable buildings.

Remember to clean surfaces before applying Adhesives, Sealants or Tapes

Before dispensing, ensure that surfaces are clean, dry and free of any dirt, dust and grease. For the best results, we recommend using CTA IPA Cleaner Degreaser.

The ideal application temperature is between 15 – 25°C.

For more information, read our two part adhesives FAQs and guide to surface preparation for adhesives and best working practice.

Both products bond the same component types and are used in the same industries. Why not purchase one of our trial kits and try both products to see which one works best for your application?

If you have any questions, don’t hesitate to contact us via the yellow chatbox, fill out our online contact form, email us at [email protected] or call us directly on +44 (0) 121 378 2909.