Double sided tapes are categorised by carrier and adhesive system. Common carriers include foam, polyester, polypropylene, and tissue, coated on both sides with emulsion or solvent acrylic, rubber, or hot melt adhesive.

View our full range of Structural and Thick Double Sided Acrylic Tapes below:

| Product | Colour | Thickness | Side / Adhesive | Temperature Range | Strength | Key Feature |

|---|---|---|---|---|---|---|

| 6110C | Clear | 1mm | Double / Acrylic | -20°C – +200°C | Very High | Structural Bonding / Transparent |

| 6110W | White | 1.1mm | Double / Acrylic | -20°C – +180°C | Very High | High Performance / Sign Makers |

| 61100 | Clear | 0.25mm | Double / Acrylic | -20°C – +180°C | Very High | Structural Bonding / Thin |

| 6116LSE | Black | 0.64mm | Double / Acrylic | -40°C – +90°C (short term 120°C) | Very High | High Performance / Low Surface Energy |

| 6117 | Grey | 1.1mm | Double / Acrylic | -20°C – +180°C | Very High | Structural Bonding |

| 6118LSE | Grey | 0.8/1.1/ 2mm | Double / Acrylic | -30°C – +180°C | Very High | Structural Bonding / Low Surface Energy |

| 6119 | Black | 1.1mm | Double / Acrylic | -20°C – +180°C | Very High | Structural Bonding |

| 6105 | Clear | 0.25mm | Double / Acrylic | -30°C – +120°C | Very High | High Performance / Thin |

| 5508 | White | 1mm | Double / Acrylic | -20°C – + 80°C | High | Ideal for Signage & Construction |

| 5508 | Black | 1mm | Double / Acrylic | -20°C – + 80°C | High | Ideal for Signage Construction |

| 5310 | White / Black | 1mm | Double / Hot Melt Rubber | -10°C – + 65°C | Medium | Ideal for Interior Applications |

| 5320 | White | 2mm | Double / Hot Melt Rubber | -10°C – + 65°C | Medium | Ideal for Interior Applications |

| 512525 | White / Black | 1mm | Double / Foam Pad | -20°C – + 80°C | Light | Ideal for Light Weight Signage |

| 4105 | Clear | 0.25mm | Double / Acrylic | -20°C – +120°C | Medium | Suitable for Lamination |

| 4114 | Off-White | 0.13mm | Double / Acrylic | -25°C – +150°C | Medium | Lightweight / Printing / Tearable |

| 43220 | Off-White | 0.05mm | Double / Perm Peel | -20°C – +120°C | Light | Lightweight / Removability |

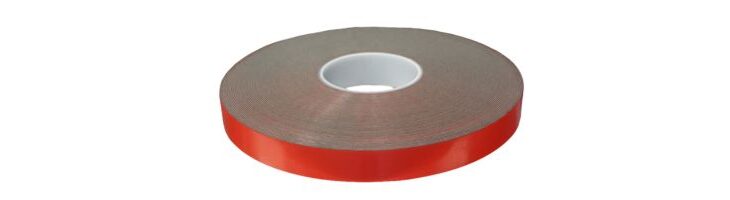

6000 Series of Adhesive Tapes: Very High Performance Acrylic Tapes

All adhesive tapes in our 6000 series are very high performance and can be used for demanding applications across various industries. Features include high temperature ratings (up to 220°C), high shear, and the ability to bond in both interior and exterior applications.

The 6000 series of foamed acrylic adhesive tapes can be used with high surface energy (HSE) materials, such as aluminium, and low surface energy (LSE) materials, such as polyolefin plastics. The 6000 series consists of our strongest adhesive tapes, all with a distinctive red filmic liner.

5000 Series of Adhesive Tapes: Thick Double-Sided Tapes

Our 5000 series of tapes is a comprehensive range of quality foam-based adhesive tapes in a range of thicknesses and from high to low density. This range of adhesive tapes includes solvent acrylic, emulsion acrylic or hotmelt on both sides for each specific application.

The 5000 series of thick double sided tapes are used on moderately uneven surfaces, plastics, metals, wood, painted plasterboard and more. Generally used for signage, extrusions, badge mounting and general construction.

4000 Series of Adhesive Tapes: Thin Double-Sided Tapes

Our 4000 series tapes includes Polyester, hotmelt tissue, high tissue tack and perm peel. This range of tapes are ideal for materials where a thin bond line is essential and a high grab.

The 4000 series thin double sided tapes are normally used for medium-weight applications and often used on plastics and light-weight metals.

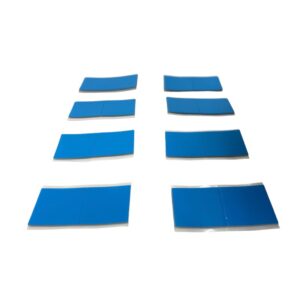

Die Cutting & Conversion

Die cutting and conversion is the process of using a die to shear pressure-sensitive adhesive tapes or foam. Having a tape die cut to suit your application requirements can vastly speed up your production process and assembly time, in addition to improving aesthetics.

If you have any questions, do not hesitate to contact us via the yellow chatbox, fill out our online contact form, email us at [email protected], or call us directly on +44 (0) 121 378 2909.