Adhesive vs welding and mechanical fixing… a thought happening much more frequently in today’s modern manufacturing times. Which would you choose for your application? What do you currently use in the work place, is it the right way? How can you be sure that a structural adhesive will be strong enough to replace welding or mechanical fixing?

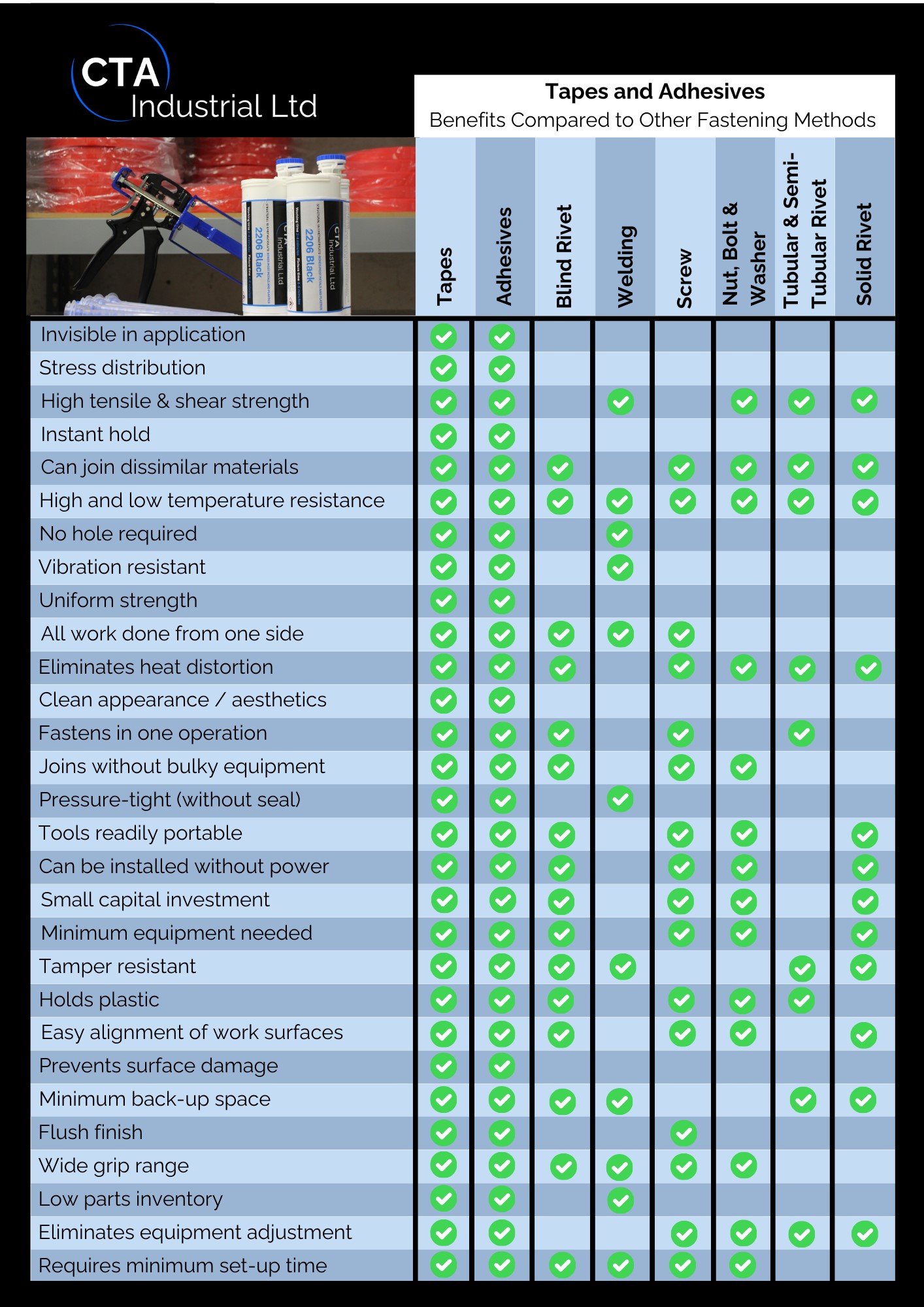

We have provided a useful reference chart to show the advantages of bonding methods at a glance:

Download this chart now (hi-res)

Thousands of industries are choosing high performance structural acrylic adhesives and replacing standard joining methods such as welding and mechanical fasteners such as rivets or bolts and we agree with them. All the answers are pointing to structural adhesive as the best way to go, read on for more information and helpful insights.

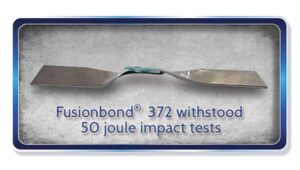

Performance and economic drivers are compelling users to let go of old methods which are costly solutions and swap them for the less expensive and more advantageous option of adhesive bonding. Yes it is time to wave good-bye to old fashioned joining processes and move into the future to the new line of high performing structural adhesives such as CTA 2105 and Fusionbond 372

Advantages of structural adhesives

Structural adhesives are cost effective and will help cut manufacturing costs by reducing the number of mechanical fasteners, spot welds and filler metal required to create a joint or attach two substrates. Adhesive joint design.

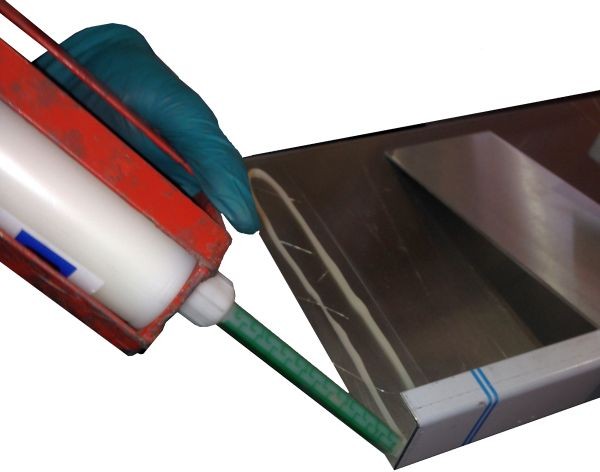

In the manufacturing process, adhesives are generally hidden between two substrates, which can offer aesthetic improvements over welding and mechanical fasteners. An adhesive bonded joint will result in a smooth, clean surface, which requires minimal surface preparation prior to final finishing. Therefore, manufacturers can eliminate labour intensive finishing costs such as sanding off imperfections from spot welding.

A huge superiority to advanced product design is that adhesives can be pre applied to parts otherwise inaccessible to mechanical fastening or welding during the assembly process. This revelation enables engineers not to be bound in their innovation of design by previous obstacles such as space or accessibility. An additional benefit is the reduction in the amount of time it takes to join substrates. Welding or installing mechanical fasteners is generally more time consuming compared to using a structural adhesive.

Structural adhesives excel in joining dissimilar substrates and materials with different thicknesses. Adhesive compensates for the differences in expansion and contraction in dissimilar materials. High performance structural adhesives can form resilient bonds and maintain strength over a wide range of temperatures.

Adhesives have the ability to eliminate stress concentration caused by spot welds, rivers, screws, and other mechanical fasteners while maintaining surface integrity. Where as a rivet or screw hole in a substrate concentrates the stress at the hole, which can potentially decrease the physical properties of the substrate, adhesives spread the load over the entire bonded area. Visit adhesive stress loads.

Using structural adhesives can reduce the weight of finished product or structure because less welding metals and mechanical fasteners are used. Additionally, eliminating screw holes and rivets in the assembly process enables manufacturers to utilise thinner, lighter materials without concerns of distortion, splitting, or crazing at the mechanically fastened site. An added benefit of eliminating the holes in metal is that it can also reduce the chance of rust and corrosion.

Unlike welding, structural adhesives have the ability to maintain the integrity of the bonded materials because there is no metal distortion or weakening due to heat when using adhesives. Structural adhesives can also increase the stiffness of structures and provide the necessary fatigue and force resistance.

Adhesive vs welding and mechanical fixing –

Who is choosing structural adhesive?

The answer is “everyone”. New applications are being developed and tested daily. Reports from the agricultural industry show workers are repairing metal fences using structural adhesives instead of welding. Marine industry manufacturers are bonding parts using structural adhesives in applications that require high resistance to chemicals like kerosene, hydrocarbon oil, mineral spirits, and ethylene glycol. The automotive industry is moving away from rivets in favour of structural adhesives due to a combination of corrosion resistance, stress relief and cost reduction. Aerospace engineers were among the earliest industries to adopt structural adhesives, mainly because adhesives can create seals that keep water out of metal fabrications while providing corrosion protection.

If you have an application and would like to discuss further with our technical team or would like a site visit or demonstration please contact us. We have a fantastic range of high performance structural adhesives specifically for product assembly application.