As we are specialists in structural adhesives, one question we get asked a lot is “Is there a difference between ‘glue’ and ‘adhesive’?” so we thought we’d start with defining the differences between the two, before we look at CTA’s product versatility.

Whilst both terms are nouns, research shows that ‘glue’ is a hard gelatin made by boiling bones and hides, that is used in solution as an adhesive. However, ‘adhesive’ is a substance that provides or promotes adhesion (source: wikidiff.com). This means that ‘glue’ is generally created from natural plant and animal sources such as starch and dextrin from bones, hides, hoofs and horns, whereas adhesives tend to be chemically/synthetically made and can rely upon inter-reactions. You can also have natural glues such as rice and wheat pastes which cure primarily by loss of moisture.

How important is the right adhesive?

There is a huge global market in glues and adhesives, which is why it’s good to be able to have us – the experts – on hand to help you decide which one is right for your application. Imagine how catastrophic it would be if the automotive industries that we work with ‘just guessed’ and got it wrong, or our sign makers didn’t know which adhesive they needed – you’d have unsafe cars and buckled brands all over the place!

Give me some examples of your versatility

You may have read on some of our previous blogs about the benefits of glass bonding and results of our stress test on steel substrates, but recently we were asked to provide a solution for a client’s kitchen renovation. As part of this project, they wanted a quartz topped breakfast bar. For this we would need to affix a mahogany panel to the underside of the quartz bar top, turn it over and allow the quartz to be suspended across the fixed points with the mahogany layer underneath. The mahogany weighed 50kg. For such an expensive investment, we had to be certain that our solution was infallible, so we used our trusty two part structural adhesive 2605. Whilst this is regularly used in the bonding of aluminium, steel and engineered plastics together, we were fully confident it would work in this application – and as a clear adhesive that lasts a lifetime, it’s perfect.

An example of the use of our 2105 structural adhesive is in a cladding application for a client called Kingdom Facades who specialise in commercial and domestic rain screen cladding products. Here the adhesive was used for both panel bonding and also as a stiffener on the top hat sections to prevent movement, as it’s so versatile it can fill gaps of up to 10mm.

Our 2206 structural adhesive has also recently been used in the automotive sector to repair a vehicle where we needed to bond an aluminium bracket to a composite of carbon fibre. This was successful not only because of the speed of bonding and its strength, but also because of its black finish.

In Summary

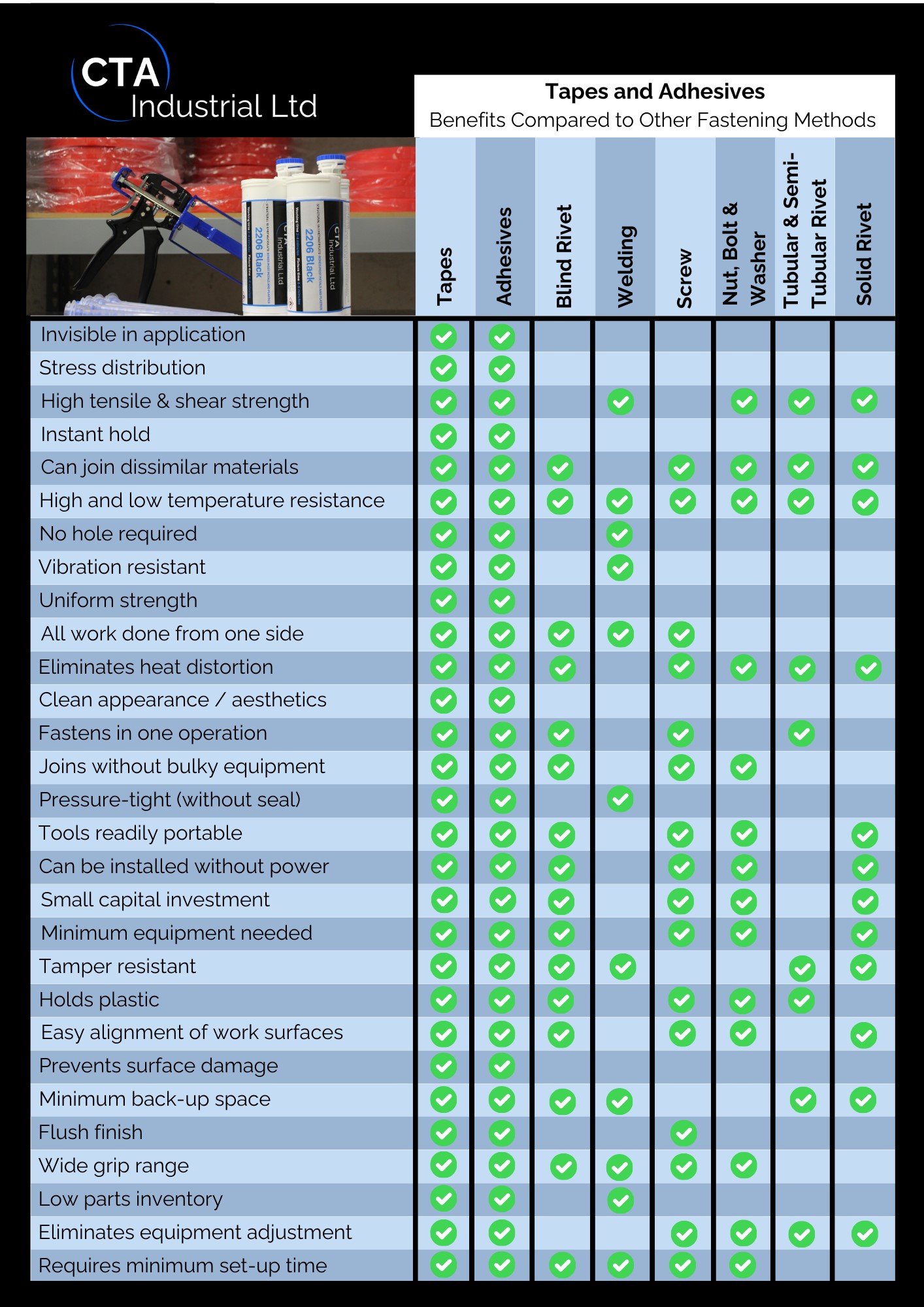

Whether you are building a boat, cladding a building, laying artificial turf, or sealing space rockets, you need to remove the risk of failure. We are finding that our customer base is expanding currently as confidence in our 2-part structural adhesives is growing, and faith is being built in their abilities. Selecting the right adhesive is a technical issue – you need to consider not only compatibility, but also the correct working time and fixing time, and whether you want a clear finish or not. Our fastening methods chart below clearly shows the benefits of adhesives compared to other fixing methods.

Call for more information today and use OUR expertise to benefit YOUR business. We provide bonds to last a lifetime. 0121 378 2909