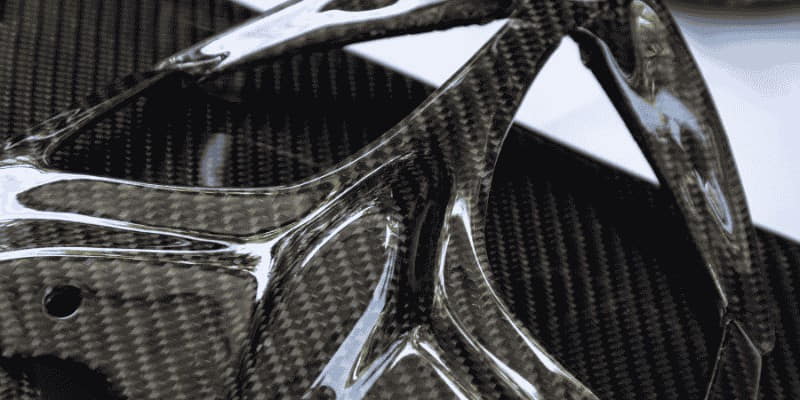

Adhesives and tapes provide solutions to numerous challenges in composites and mouldings manufacturing. They help improve bonding, reduce stress concentrations, prevent delamination, offer better sealing, and improve overall design flexibility—all while contributing to cost and weight reductions. These benefits make adhesives and tapes indispensable in industries such as automotive, aerospace, marine, and construction, where composite materials are increasingly used.

The following are typical problems within the Composite and Moulding sector that can be solved using adhesives, tapes and sealants:

| Problem | Solution | Product Category |

|---|---|---|

| Bonding different materials | Structural adhesives can form strong, durable bonds on a wide range of composite material. | Structural Adhesives |

| Stress distribution | Adhesives distribute stress more evenly over the bonding surface, reducing the risk of localized stress concentrations. | Structural Adhesive |

| Delamination and Surface Cracking | Adhesives, such as epoxy or polyurethane-based systems, can help bond composite layers together, preventing delamination | Toughened Epoxy |

| Surface Preparation and adhesion issues | Surface preparation products (such as primers or adhesion promoters) and specific adhesive formulations designed for difficult-to-bond surfaces can significantly improve adhesion. | Primer

|

| Sealing gaps and preventing leaks | Tapes, such as sealing or gasket tapes, can effectively seal gaps to prevent leakage of fluids or gases. | Structural Tapes |

| Durability in Harsh Environments | High-performance adhesives and tapes are often designed to withstand extreme temperatures, UV exposure, and moisture. | Composite GRP Adhesive |

| Manufacturing efficiency | Adhesives and tapes streamline the manufacturing process by allowing for faster assembly without the need for time-consuming operations like drilling, welding, or curing. | Structural Adhesive |

Here are some typical applications for adhesives and tapes in composites and mouldings sectors:

- Composite bonding

- Interior assembly

- Sealing and insulation

- Glass bonding

- Gasketing

- Waterproofing

We believe that adhesives and tapes are valued in the composite and mouldings sector for their ability to provide strong, durable, and often lightweight bonds that can withstand harsh conditions such as temperature fluctuations, vibrations, and moisture exposure. They also allow for faster production cycles and offer flexibility in terms of design and material compatibility.

Suitable Products for Composites and Mouldings:

We offer expert adhesive and sealant advice for the composites and moulding sector and can recommend best practices for metal and composite bonding and adhesive safety and handling tips. We can also help when trouble shooting and advise on how to select the correct adhesives and tapes for composite and moulding manufacturing. If you would like to discuss any of your application concerns contact us.

Here are some of our best-selling products for the Composites and mouldings sector as well as uses for adhesives and tapes. They range from structural adhesives, such as Toughened Epoxy Resin, and high strength tapes to toughened epoxy resin and preparation primer.

Two Part Structural Adhesive 2206

CTA 2206 is a 10:1 ratio black methacrylate adhesive, capable of bonding most metals, plastics and composites.

Two Part Structural Adhesives 2206

Toughened Epoxy Resin 2605

Toughened epoxy resin 2605 is an epoxy adhesive capable of bonding aluminium, steel, engineered plastics and composites together.

Primer

The CTA primer for adhesives & tapes are an adhesion promoter for hard to bond substrates available in 236.5ml units. This product can be used on materials such as polyethylene, polypropylene, ABS, PET/PBT blends, concrete, wood, glass, metal and painted metal surfaces.

Structural Tapes

Clear foamed acrylic tape 6110 is an ultra-high performance, optically clear, double sided, foamed acrylic gel tape. Used for various demanding bonding applications, such as signage, panel production and composites.

If you have any questions, don’t hesitate to contact us via the yellow chatbox, fill out our online contact form, email us at [email protected] or call us directly on +44 (0) 121 378 2909.