The Ministry of Defence (MOD) faces various manufacturing challenges that can be effectively addressed using advanced adhesive technologies. Hernon Manufacturing, Inc., a leader in high-performance adhesives, sealants, and dispensing equipment, offers specialised solutions well-suited for military and defence applications.

Defence-Grade Adhesives and Sealants for Precision Applications

Hernon Manufacturing has a proud history of supporting the defense industry and the U.S. military with innovative adhesive solutions for defense manufacturing. Our advanced defense-grade adhesives and sealants are engineered to meet the rigorous demands of military applications, providing unmatched reliability, strength, and performance in even the most challenging environments.

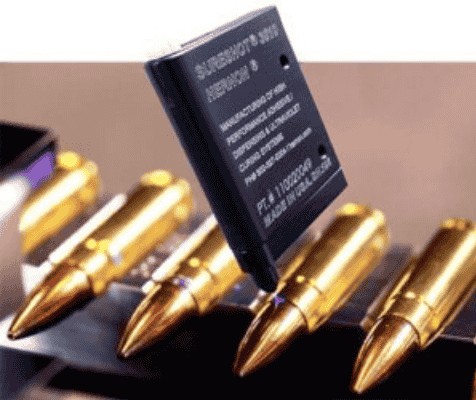

MILITARY-GRADE AMMUNITION SEALANTS FOR SUPERIOR PROTECTION

Hernon Manufacturing specialises in high-performance ammunition sealants designed to meet the rigorous demands of military and commercial applications. Our military-grade ammunition sealants provide unparalleled protection against moisture, corrosion, and environmental exposure, ensuring long-term reliability and performance.

Engineered for military-grade applications, our ammunition sealants enhance the durability of cartridges, primers, and bullet casings. By forming a secure, moisture-resistant barrier, these sealants prevent misfires, contamination, and degradation caused by harsh conditions.

Why Choose Hernon’s Ammunition Sealants?

- Superior Moisture Protection – Prevents water ingress for increased longevity.

- Corrosion Resistance – Shields against environmental and chemical exposure.

- Fast Cure Technology – Rapid drying for increased production efficiency.

- Custom Formulations – Tailored solutions for specific military and commercial requirements.

From large-scale military contracts to commercial ammunition production, Hernon’s ammunition sealants for military-grade applications are trusted worldwide. Discover how our cutting-edge solutions can enhance your ammunition’s performance and durability.

Products available:

Blank Ammunition Sealant 48642

External Ammunition Sealant 59521, 59541, 59621, 59681, 76040, 76041, 76060, 76061, 76070, 76081, 76082, 76083, 76084, 76984

Blank Ammunition Sealant 48641, 48643, 53162,

Advanced Threadlocking Solutions for Secure Fastening

Hernon Manufacturing provides industry-leading threadlocking adhesives designed to prevent loosening, leakage, and failure in threaded assemblies. Our solutions range from low-strength threadlocker for easy disassembly to medium-strength threadlocker for general-purpose applications and high-temperature threadlockers for extreme conditions.

Engineered for precision and reliability, our military-spec thread locking adhesives meet the highest industry standards, ensuring durable fastening for aerospace, automotive, and industrial applications. Whether you need the best threadlocker for vibration resistance or a high-temp threadlocker for extreme heat environments, Hernon has a solution tailored to your needs.

Products available:

Nuts N’ Bolts 223, 227, 230, 232, 234, 237, 240, 431, 425.

Why Choose Hernon’s Threadlocking Adhesives?

- Prevents Loosening – Secures locking thread bolts and thread locking screws against vibration.

- High-Temp & Military-Spec Options – Meets stringent industry standards.

- Versatile Strength Levels – Choose from low-strength, medium-strength, or high-temperature threadlockers.

- Industrial-Grade Performance – Trusted by aerospace, automotive, and manufacturing industries.

For unmatched durability and security, Hernon’s threadlocking adhesives provide the ultimate fastening solution. Explore Hernon’s Threadlocking Solutions Today!

Other typical applications for Hernon adhesives in the MOD manufacturing sector:

- Structural Bonding

- Electronic assembly and potting

- Sealing and gasketing

- Thread locking and Sealing

- Component retention

- Chemical and Environmental resistance

We believe that Hernon adhesives are particularly valued in MOD applications for their high-performance characteristics, such as rapid curing, thermal resistance, chemical resistance, and the ability to bond dissimilar materials.

Suitable Products for MOD:

Hernon adhesives provide innovative solutions to many of the MOD’s manufacturing challenges, from weight reduction and corrosion protection to rapid repair and noise reduction. Implementing these solutions can enhance performance, reduce maintenance, and improve reliability across various military applications.

We offer expert adhesive and sealant advice for the MOD sector and can recommend best practices for metal and composite bonding and adhesive safety and handling tips. We can also help when trouble shooting and advise on how to select the correct adhesives and sealants for MOD equipment manufacturing. If you would like to discuss any of your MOD application concerns contact us.