Stress loads on adhesive joints can vary from application depending on the substrates being bonded and how pressure/force is loaded upon a joint. It is difficult to determine how differing stress loads on adhesive joints may affect the overall performance and durability of a bonded joint within an application. Various tests can be performed to ascertain each adhesives optimum performance and also what performance can be achieved when differing stresses are applied to a bonded joint. Stress is a force applied to a bond, usually expressed in N/mm² (Newton’s per square millimetre) or MPa (Mega Pascals).

Below you will see a variety of diagrams with an explanation about the stresses commonly found in adhesive bonds. One type of stress is Impact stress which occurs when a sudden force or shock is applied to a joint. for more information on joints view adhesive joint design.

Tensile stress: to pull an object apart. It also tends to elongate an object.

Compressive stress: the opposite of tensile stress, compressive stress tends to squeeze an object together.

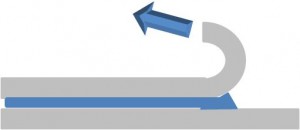

Shear stress: created by two surfaces sliding over one another.

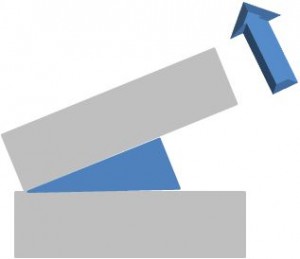

Cleavage stress: occurs when a joint is being opened at one end.

Peel stress: occurs when a flexible substrate is being lifted or peeled from the other substrate.

To speak with out technical team on any of the above contact us.