In both automotive manufacturing and the aftermarket, the versatility of structural tapes and adhesives is transforming how vehicles are assembled, repaired, and customised. They offer efficient, cost-effective, and high-performance solutions for automotive manufacturing, enhancement, servicing and repair.

The following are typical problems within the automotive and aftermarket sector that can be solved using adhesives, tapes and sealants:

| Problem | Solution | Product Category |

|---|---|---|

| Weight reduction | Structural Adhesives and tapes can replace heavy metal, mechanical fasteners. | Structural Adhesives |

| Improvement to structural integrity | Adhesives bond with a more uniform stress distribution which offers better crash protection. | Structural Acrylic |

| Corrosion Resistance | Sealants can be applied to joints, seams and edges to provide a barrier against moisture and chemicals. | Sealants |

| Vibration and soundproofing | Tapes can act as sound and vibration dampeners. Structural adhesives reduce the movement of parts resulting in less noise. Threadlockers prevent loosening, leakage, and corrosion. | Structural Tapes |

| Fast, efficient production | Adhesives, tapes and sealants allow for faster assembly and reduced tooling needs. | Structural Adhesives |

| Efficient aftermarket repair and maintenance | Structural adhesives and tapes provide a convenient and effective way to repair cracked panels, loose trim, and other damaged parts without the need for welding or other complex methods. | Structural Adhesives |

| Loosening of joints due to vibration | Threadlockers can prevent loosening, leakage and corrosion in metal assemblies. | Lockers |

Here are some typical automotive and automotive aftermarket applications for structural adhesives, tapes and sealants:

- Body assembly

- Bonding interior parts

- Surface protection

- Sound dampening

- Sealing and Gasketing

- Interior customisation

- Sealing joints and gaps

Suitable Products for Automotive Manufacturing:

We believe that overall, structural adhesives, tapes, and sealants play critical roles in improving the performance, safety, and durability of vehicles while also contributing to the efficiency and ease of manufacturing and aftermarket activities.

We offer expert adhesive advice for the Automotive and automotive aftermarket sector manufacturing and can recommend best practices for metal and composite bonding and adhesive safety and handling tips. We can also help when trouble shooting and advise on how to select the correct adhesive for automotive manufacturing and repair. If you would like to discuss any of your Auto design concerns, then please contact us.

Here are some of our best-selling products for the automotive sector as well as uses for adhesives and tapes. They range from structural adhesives and high strength tapes to sealants and application specific solutions.

Structural Adhesives

Our two-part structural adhesive is a Methacrylate acrylic adhesive, used to bond metal, steel, aluminium and even dissimilar metals together. Structural Adhesive distributes stress uniformly across bonded surfaces with no surface interference. These adhesives form a protective seal against the elements and are lightweight when compared to metal components. Adhesives can be applied quickly and cure without extensive tooling and alignment.

Sealants

Non-solvent, high grab and flexible all purpose multi-purpose polyurethane adhesive sealant 12126. Ideal for a wide variety of sealing and bonding applications.

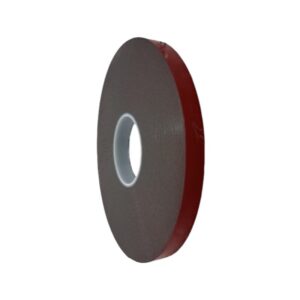

Automotive foam tape

Automotive foam tape 6118LSE is a high performance, double-sided grey adhesive tape. For demanding applications in the automotive industry.

Threadlockers

Thread Lockers are single-component adhesives applied to the threads of fasteners to prevent loosening, leakage, and corrosion. We offer a variety of Threadlockers with differing strength capabilities from low to high.