Adhesive joint design can vary tremendously dependent upon materials, dimensions and various limitations. This section has been put together to help determine and understand the numerous ways of bonding joints together and how this can benefit in strength and performance or adversely be detrimental to the overall performance and durability of the adhesive joint.

Their are many different attributes that need to be considered when metal bonding, these factors are types of joints, types of stresses and distribution of stress across the joint.

Types of joints

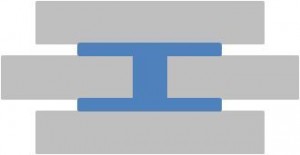

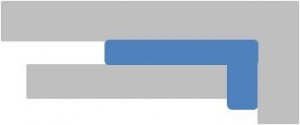

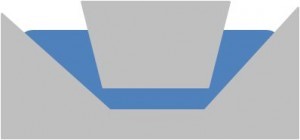

Please view the images on this page to assist in understanding popular joints. These images are cross sections of joints, grey signifies your chosen metal and blue signifies adhesive.

Double lap joint: Incorporates two lap shear joints in one.

Butt joint: Formed by bonding two objects end to end.

Joggle lap joint: Offset joint very similar to the lap joint.

![]()

Lap/Overlap joint: Formed by placing one substrate partially over another substrate. ![]()

Scarf joint: An angular butt joint. Cutting the joint at an angle increases the surface area.![]()

Cylindrical joint: Uses a butt joint, to join two cylindrical objects.![]()

Single or Double strap joint: A combination overlap joint with a butt joint.

Biscuit Lid Joint: a variation on a joggle lap joint

Flange Joint: A variation on an overlap joint

Toggle joint: Formed by fitting the two substrates together in a ‘tongue and groove’ type formation

Stepped lap joint: a variation of a lap shear joint

If you would like to discuss adhesive joint design further, please contact our technical team.